Tooling & Workholding

Filter by Process Zone:

U.S. Cutting Tool Consumption Down Slightly

The $205.6 million in orders during February were down 4.4 percent from the previous month.

Weiler Abrasives Receives Award

They receive the People’s Choice Innovation Impact Award at the 2019 Industrial Supply Association Convention.

All Aboard

After some accidents and trials with less efficient alternatives that caused problems and delayed work, this railway group got on board with replacing their old grinding and cutting devices with new equipment that would eliminate workplace risks without sacrificing productivity.

Kitagawa North-Tech Reorganizes Sales Staff

Shawn Luschei is vice president of sales and marketing, Dale Anderson is inside sales manager, and Ryosuke Yatsunami is business development manager.

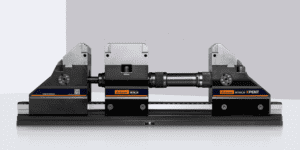

Multi-Tasking on Hold: Clamp Two Parts with One Vice

For more efficient clamping that generates a measurable increase in productivity on 3-axis and 5-axis machines, a new center jaw for the GARANT Xpent 5-axis vice from Hoffmann can be fit to the base rail to clamp two workpieces with only one vice and process them in a single operation.

No Job Too Small

The use of smaller abrasives and supporting tools is growing in shops that are less concerned about stock removal and heavy deburring but need to produce parts with fine finishes, want more control for less gouging of parts, and desire improved ergonomics.

Manufacturing vs. Fabrication: How to Make the Distinction

Is your operation highly repeatable or do you require more equipment and personnel flexibility for a wider range of work? Knowing the difference is important in selecting the right equipment and process optimization needed to maximize productivity, save time and money.

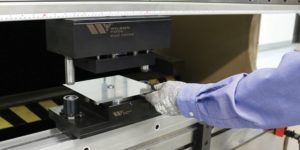

Need More Punching Capacity? Turn Your Press Brake Into a Punch Press

Does limited punching capacity and outsourcing lead times cause production delays in your shop? Here is a simple, affordable and effective system that can expand the capabilities of your press brakes, help streamline operations and eliminate the need for outsourcing or purchasing new equipment.

The Jig is Up: Flexible Part Positioning

Whether welding or handling, the flexibility of a six-axis robot arm is tough to beat. A single workcell with multiple robots can complete several processes with great reliability for the consistency needed to maintain 24/7 operations in an industrial climate that lacks skilled workers.

Seco Tools Names New Director

Bill Barcelona is now their director of customer experience.

Kyocera Builds Smart Factory

This facility in Shiga, Japan, will develop their own production equipment to strengthen their use of robotics and AI technology.