Material Handling

Filter by Process Zone:

Custom Forklift Attachment Enhances Stamping Plant Productivity

Caldwell Group tool facilitates delivery of 11-to-12-ton steel coils at MiTek USA.

OnRobot Grippers Receive UR + Certification for Seamless Operation

The certified URCap software provides a unified interface for OnRobot’s new versions of RG2, RG6, and VG10 grippers with Universal Robots (UR).

Dynamic Scrap Handling Increases Coil-Fed Laser Blanking Speed

Coil-fed laser blanking systems from LaserCoil rely on a series of dynamic profile conveyor lanes that independently adjust, reposition and automatically shed scrap to maintain a clear path for the cutting process.

Automatic Garnet Feeding Increases Waterjet Cutting Productivity

The JET-FEED Garnet Delivery System from Flexicon automatically feeds garnet directly from bulk bags to waterjet cutters to eliminate worker fatigue, potential injury, labor, spillage, dust, downtime and higher material cost associated with manually dumping heavy bags.

How to Maximize Sorting Flexibility for Unloading Laser Cut Parts

The BySort add-on module unloads and sorts individual parts by job to expand the flexibility of the ByTrans Cross automation system for loading and unloading laser cutting systems from Bystronic.

Bilsing Launches New Website

They present their expanded capabilities and equipment for the press shop and other sectors.

Skilled Hands

Humanoid manipulators with an ever-higher flexibility of motion are here and will grow in demand in the future because the closer human beings and robots work together, the greater the relevance of five-fingered gripping hands. Here’s why.

Questions to Ask Before Selecting Your Next Air Gripper

Choosing the proper gripper will result in optimized performance, uptime and operator safety,

but only if all operational and design factors are adequately weighed before the decision is made.

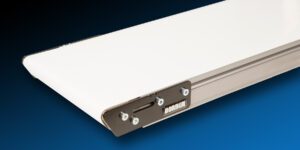

Movers and Shakers: Conveyors

In the dawning Age of the Smart Factory, the workhorse of the shop floor is getting sleeker, smarter, more efficient and much more flexible in moving material from one point to another in more applications than ever before.

Vacuum Cleaning System for Below-Floor Mechanical Metal Chip Conveyors

To reduce cleaning time and increase machine tool uptime, the Central Vacuum Cleaning System from VAC-U-MAX collects and deposits wet or dry cast iron, steel, aluminum and composite chips, abrasive materials and metal debris onto existing below-floor mechanical chip conveyors.

Automated Orbital Wrapping with Multi-Pallet Accumulation Zones and Integrated Weighing

Multi-pallet accumulation zones and integrated load cells on the fully automated Perfect Storm wrapping system from TAB Industries improve efficiency, keep lift trucks from being idle, and eliminate extra freight charges and delays due to inaccurate weights.

Automated Chip Handling and Coolant Filtration for Machining Operations

The flexible, cost effective, self-cleaning EcoFilter conveyor and filtration system from Jorgensen easily fits the existing coolant tanks of machining center and lathe envelopes and can be retrofitted with a kit.