Friction Welding Systems

Filter by Process Zone:

New VRTEX® 360 Compact Virtual Reality Trainer from Lincoln Electric

Lincoln Electric expands its VR technology with a tabletop welding simulator that delivers eco-friendly welding training on a smaller footprint.

Innovative Aluminum Pneumatic Tubing for Welding Cells

PM aluminum tubing can be located closer to the welding process than laminated tubing, creating a more efficient pneumatic setup.

New Millermatic 355 MIG Welder Supports a Variety of Materials

Miller Electric Mfg.’s easy to use machine allows operators to weld a variety of materials in many work environments.

Resistance Welders Prepared to Tackle the Most Demanding Jobs

The innovations taking place within the resistance welding market continue to make the process extremely cost efficient.

Two in One: Hybrid Milling/Friction Stir Welding Machine

Mazak expands its line of multitasking machining centers with the VTC-300C FSW, a milling machine with friction stir welding (FSW) package for joining alloys with low melting points. Machine also features full traveling-column design, automatic tool changer, and 40-taper spindle.

Prototype and Low Volume Friction Welding of Dissimilar Materials

Coldwater Machine welds prototypes or small batches of various parts that join bar stock and tubes, rods, cylinders, fasteners, studs, nuts and fittings, as well as drills, rods and hand tools with carbide inserts, heat sinks, air bag inflators, electrodes and shafted components that can be made of dissimilar materials.

Mazak Acquires MegaStir

This deal expands their multi-tasking technology in friction stir welding applications.

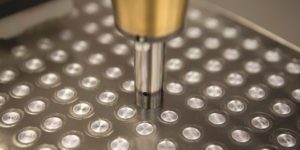

Friction Stir Spot Welding of Aluminum and Other Lightweight Materials

The SpotMeld system from Coldwater Machine can weld lightweight materials such as aluminum, magnesium, non-ferrous and dissimilar sheet material without adding additional weight to the structure, producing a weld that is near original material strength.

Coldwater Machine Opens Dayton Engineering Office

This new 2,300 sq ft location houses eight engineers to support their expanding business needs.

Coldwater Machine Partners in LIFT/Boeing Welding Project

They are participating in the Processing and Properties Database for Refill Friction Stir Spot Welding of Aerospace Materials technology project.

New Application Engineering Manager at Coldwater Machine

Nathan Wenning is now responsible for their quote development and sales order release process.

Linear Friction Welding: Not Just for Aerospace Parts Production

High cost and large size have always been the main reasons why linear friction welders have seen limited use outside of aerospace applications. But that is changing with a new line of affordable LFW systems that have a much smaller footprint and utilize a patented electro/mechanical oscillation device that is new to the world of linear friction welding.