Plasma Cutters

Typically used to cut steel, stainless steel, aluminum, brass, copper and other conductive metals, a plasma cutter blows compressed oxygen, air, inert or other gases (depending on the metal being cut) through a focused nozzle at high speed toward the metal, forming an electrical arc within the gas between an electrode near the gas nozzle and the metal itself. This electrical arc ionizes some of the gas to create an electrically-conductive channel of plasma. As electricity from the cutter torch travels down this plasma, it delivers enough heat to melt through the metal as the high velocity plasma and compressed gas blow the hot molten metal away, separating (cutting through) the metal.

Faster, More Consistent Consumables Ensure High-performance Applications

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Airgas enables your fabrication operation to “fill your potential.”

How IIoT can improve efficiency, quality and safety.

Automation, cobots and robots facilitate resilience and provide numerous competitive advantages to the metalworking industry.

Cutting-edge real time visioning systems and advancements in cobot welding ensure precision, reproducibility, and controlled and reliable production.

RoboVent’s new Spire series now available in three CFM ratings for enhanced flexibility.

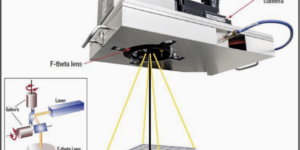

Quick and accurate point-to-point positioning can shave seconds off cycle times.

All-in-one Plasma Cutter Increases Productivity and Opportunity in a Short Time for SL Chasse in New Hampshire

With VideoHGG Profiling Equipment’s RoboRail addresses the day-to-day production issues of miscellaneous metal fabricators. The machine is flexible and sturdy, making it capable of processing parts in a variety of sizes, shapes and metals.