Inverter Welders

An inverter-based power source electronically increases and controls the frequency of the primary power supply before it enters the transformer, using electronic switches to turn power on and off extremely quickly and convert the power supply into a lower usable output voltage with improved electrical characteristics for welding, such as faster response time and more control for pulse welding.

Faster, More Consistent Consumables Ensure High-performance Applications

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Airgas enables your fabrication operation to “fill your potential.”

Automation, cobots and robots facilitate resilience and provide numerous competitive advantages to the metalworking industry.

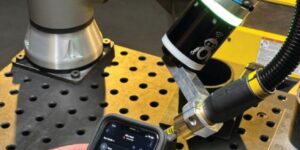

Cutting-edge real time visioning systems and advancements in cobot welding ensure precision, reproducibility, and controlled and reliable production.

Moving beyond high-mix, low-volume welding work, cobots are more and more suitable for laser welding, becoming increasingly more portable, and are incorporating coordinated motion to optimize cycle times.

A new flatsheet laser machine from TRUMPF, the TruLaser Series 3000 Bevel Cut Edition, prepares parts for welding while cutting. The machine automatically creates bevels on parts, and the solution is suitable for medium to thick sheet material and enables a wide range of edge geometries.

Simplify tasks and reduce equipment needs with a compact, lightweight machine that does it all.

Latest advancements of the Miller Copilot Collaborative Welding System optimize the weld path for higher quality welds with touch sensing and seam tracking for a more intuitive user experience.