Engine Driven Welders

Typically transported on a truck or trailer for welding on outdoor jobsites and as a backup generator, these machines use a gasoline, diesel, or propane fueled engine coupled to an electrical generator to produce power for Stick, TIG, MIG and Flux-Cored welding. The electricity generated by an engine driven welder powers fans, pumps, air compressors or other electrical tools commonly found on jobsites.

Airgas’ Sustainable Welding Innovations Improve Quality, Productivity and Efficiency

Airgas enables your fabrication operation to “fill your potential.”

Airgas enables your fabrication operation to “fill your potential.”

How IIoT can improve efficiency, quality and safety.

Cutting-edge real time visioning systems and advancements in cobot welding ensure precision, reproducibility, and controlled and reliable production.

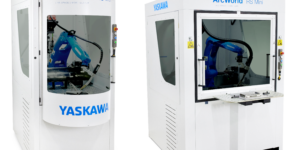

Moving beyond high-mix, low-volume welding work, cobots are more and more suitable for laser welding, becoming increasingly more portable, and are incorporating coordinated motion to optimize cycle times.

How pre-engineered weld cells can benefit business of all sizes.

Simplify tasks and reduce equipment needs with a compact, lightweight machine that does it all.

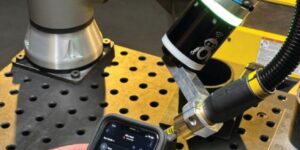

Latest advancements of the Miller Copilot Collaborative Welding System optimize the weld path for higher quality welds with touch sensing and seam tracking for a more intuitive user experience.

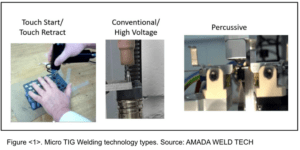

AMADA WELD TECH shares expert insights into technology that offers mechanically robust and electrically conductive joints.