Brazing

Faster, More Consistent Consumables Ensure High-performance Applications

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Airgas enables your fabrication operation to “fill your potential.”

Moving beyond high-mix, low-volume welding work, cobots are more and more suitable for laser welding, becoming increasingly more portable, and are incorporating coordinated motion to optimize cycle times.

Regardless of your skill level, using subpar equipment will put your work at risk or make it harder to optimize output.

Get the most from your robotic welding investment through careful planning and continued monitoring.

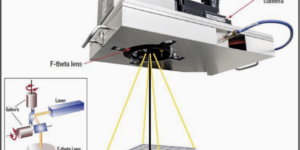

A new flatsheet laser machine from TRUMPF, the TruLaser Series 3000 Bevel Cut Edition, prepares parts for welding while cutting. The machine automatically creates bevels on parts, and the solution is suitable for medium to thick sheet material and enables a wide range of edge geometries.

Quick and accurate point-to-point positioning can shave seconds off cycle times.

Accelerating time to market and ensuring quality with virtual assembly.