Vises and Vise Jaws

Vises consist of two parallel jaws that clamp together to securely hold a workpiece. In most vises, one jaw is movable by lever or screw, while the other jaw is fixed in place. Vises are made of various materials and can include temporary jaws of sheet copper or leather to cover the permanent surfaces when soft workpieces are being machined. Some vises are able to swivel or pivot in relation to the base, so that the workpiece can be held in a variety of positions. Vises are manufactured in numerous sizes for a variety of uses, from portable hand vises bolted to a workbench, to pipe vises used by plumbers, to angle and rotary vises.

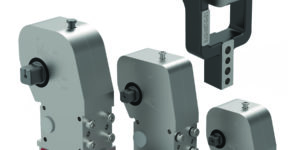

Robotic Tool Changers Increase Flexibility and Uptime

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

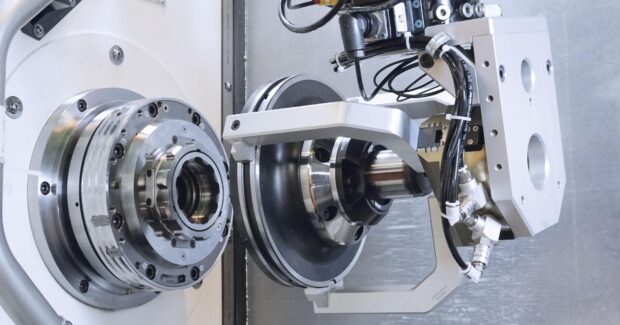

Machine tool accessories reduce downtime and speed up your machining operations.

Modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling.

Secure your workpieces with robust clamping forces, innovative designs and quicker setups.

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

The new alignment tool is ideal for use with boiler- and single tube high-temperature and high-pressure applications and sets up fast.

Stafford Manufacturing Corp.’s weldable flange collars made from 1018 steel to let users weld components instead of using fasteners.

Sandvik Coromant’s QS™ Micro delivers unprecedented precision in sliding head machines, which promises precision, security and repeatability, and maximized machine utilization.