Threading Tools

This category includes systems that create screw threads in a workpiece. Threading is either performed by subtractive methods (thread cutting), deformative or transformative methods (rolling, casting, and molding), or additive methods (3D printing, etc.). Common subtractive threading tools are taps and dies, which incorporate longitudinal flutes to cut screw threads within a hole or nut. Taps are used to cut or form the female portion of a threaded pair, dies form the male portion. Taps and dies are typically formed from high-speed steel or carbon tool steel.

Extending Cutting Tool Life

Minimize tool replacement expenses, while maintaining consistent and quality output.

Minimize tool replacement expenses, while maintaining consistent and quality output.

With a mission to develop a next-generation bit design, Salvation Drilling Tools enlisted Sandvik Coromant and its advanced machining knowledge to help pioneer a new three-cone rotary rock bit.

Solid carbide drills support innovative manufacturing, and due to their higher metal efficiencies contribute to and maximize a shop’s productivity levels.

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Sandvik’s PrimeTurning machining method supports competition among manufacturers, both for electric automobiles and other types of electric vehicles.

Monaghan Tooling Group introduces Vergnano P900 forming taps, , designed for blind or thru holes in mild or stainless steel, light alloys and super alloys.

Walter USA’s M2029 octagon face mill boosts productivity when finishing cast iron and steel parts.

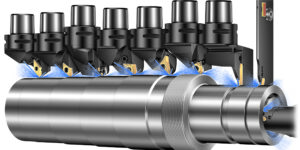

Sandvik Coromant introduces automatic tool change for improved machine utilization and productivity. This unique solution enables unmanned production, free from manual handling, for improved machine utilization and increased output.