Positioners

This category includes systems to which workpieces are affixed, which then offer a range of motion to either reduce operator fatigue or to precisely position the workpiece for the manufacturing process. Positioners can be capable of 360-degree rotation. Positioners are typically used in the welding of shafts, wheels, and pipes, the mounting of welding equipment, and rotating workpieces that have large offset loads. Other positioners are used to precisely and safely position drive trains and adjust their tension.

Robotic Tool Changers Increase Flexibility and Uptime

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

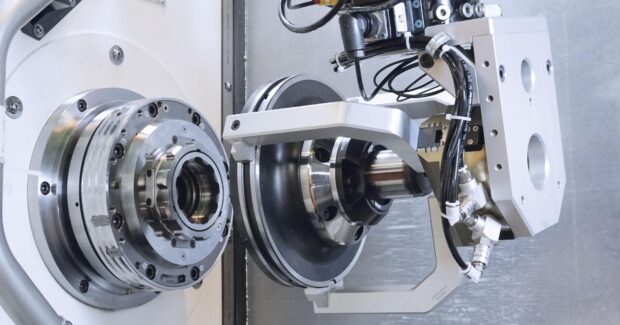

Machine tool accessories reduce downtime and speed up your machining operations.

With a mission to develop a next-generation bit design, Salvation Drilling Tools enlisted Sandvik Coromant and its advanced machining knowledge to help pioneer a new three-cone rotary rock bit.

Manufacture with sharp cuts to produce precise shapes for your customers.

The large addition will more than double the existing manufacturing space. The project strategically supports the steady business growth from existing and new products, the growth of key channel partners, and the recent acquisition of Walker Magnetics. “The new space…

Stafford Manufacturing Corp.’s weldable flange collars made from 1018 steel to let users weld components instead of using fasteners.

Sandvik Coromant’s QS™ Micro delivers unprecedented precision in sliding head machines, which promises precision, security and repeatability, and maximized machine utilization.

But fear not; we’re here to shine a light on those dark corners and show you that workholding doesn’t have to be a nightmare.