Fixturing Systems

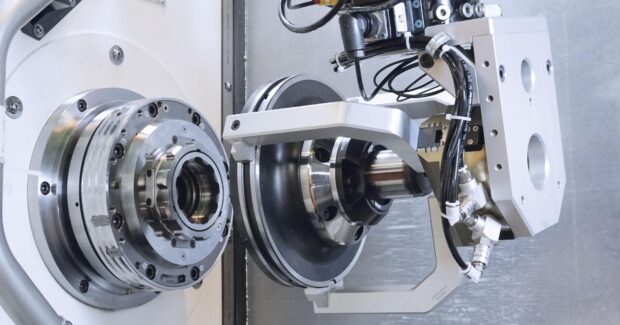

Fixturing systems provide secure mounting points for workpieces, supporting the workpiece in the manufacturing process so that each piece maintains conformity and can be interchanged with any other piece manufactured in the run. Most fixtures incorporate a solid component fixed to the floor of the work area or to the machine body, and are considered immobile relative to the machining bit. Fixturing systems can be generally designed to accommodate multiple uses, adjustable like clamps, or highly customized to accommodate specific workpiece designs.

Robotic Tool Changers Increase Flexibility and Uptime

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

Machine tool accessories reduce downtime and speed up your machining operations.

FABTECH Heads to Chicago’s McCormick Place from September 11-14!

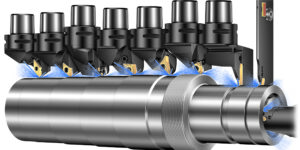

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Manufacture with sharp cuts to produce precise shapes for your customers.

The new alignment tool is ideal for use with boiler- and single tube high-temperature and high-pressure applications and sets up fast.

Stafford Manufacturing Corp.’s weldable flange collars made from 1018 steel to let users weld components instead of using fasteners.

But fear not; we’re here to shine a light on those dark corners and show you that workholding doesn’t have to be a nightmare.