Collets

A subcategory of chucks, collets incorporate a tapered outer sleeve and an inner cylindrical surface that fits around a tool or workpiece. Collets are typically divided into woodworking and metalworking uses. In woodworking, collets are often used to hold cutting bits in routers, drill presses and other machinery. In metalworking, collets are typically used for holding round bars or tools, but can also be found in hexagonal, square, and custom-shaped configurations.

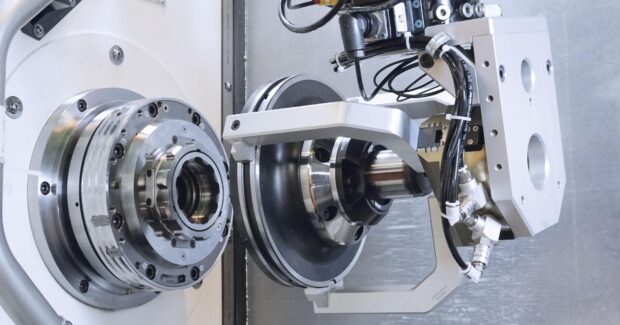

Robotic Tool Changers Increase Flexibility and Uptime

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

By enabling high-speed, precise, and flexible tool changes, robotic tool changers maximize uptime and streamline production workflows.

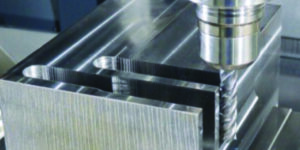

Machine tool accessories reduce downtime and speed up your machining operations.

Modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling.

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

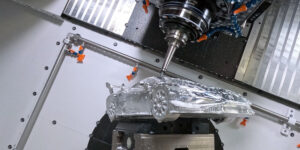

Blaser Swisslube, in collaboration with its industry partners, demonstrates machining strategies for complex parts.

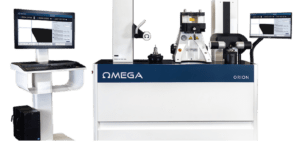

REGO-FIX partners with Omega TMM to create the ORION powered by REGO-FIX – a tool measuring machine using REGO-FIX’s powRgrip tool holding system with Omega TMM’s presetting technology.

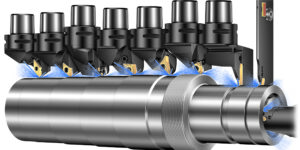

Sandvik Coromant’s QS™ Micro delivers unprecedented precision in sliding head machines, which promises precision, security and repeatability, and maximized machine utilization.