Chucks

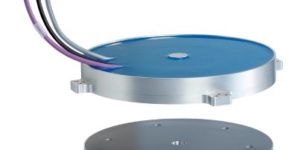

Chucks comprise a category of universal holding devices used in turning applications, capable of interior diameter or outer diameter (ID or OD) clamping. Chucks feature two to eight jaws, catered to fit the shape of the workpiece. Lathe chucks can be mounted vertically, horizontally, or inverted, and are operated either manually, electrically, hydraulically, or pneumatically. Along with standard jawed chucks, magnetic, electrostatic, and vacuum chucks also exist for custom applications.

Trailblazing Accessories Ensure Quicker Production Cycles and Increased Output

Machine tool accessories reduce downtime and speed up your machining operations.

Machine tool accessories reduce downtime and speed up your machining operations.

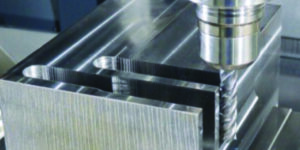

Modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling.

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

Getting the most out of your shop’s tool and workholding products leads to increases in uptime.

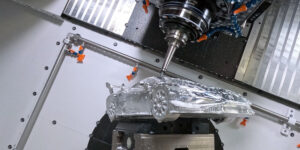

Blaser Swisslube, in collaboration with its industry partners, demonstrates machining strategies for complex parts.

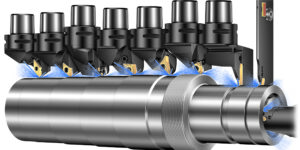

Sandvik Coromant’s QS™ Micro delivers unprecedented precision in sliding head machines, which promises precision, security and repeatability, and maximized machine utilization.

But fear not; we’re here to shine a light on those dark corners and show you that workholding doesn’t have to be a nightmare.