Tube & Pipe Fabrication

Sawing, cutting and deburring, bending, notching, slotting, piercing, drilling, welding or other fabrication of tube and pipe lengths to produce individual parts meeting desired specifications used for assembly. Common types of machinery used to perform these operations range from manual and semi-automated tube benders, end formers, tube notchers and tube cutters to fully automated laser tube cutting systems that complete multiple fabrication steps in one machine.

Advancements in Cutting Systems Transform the Manufacturing Landscape

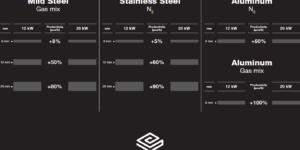

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Fiber lasers and profiling equipment will be showcased in Orlando at Fabtech.

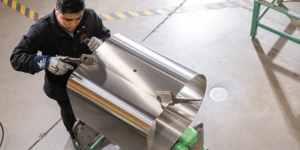

Davi’s advanced HMI controls allow shops such as AlumiTank to easily edit material libraries so they can further fine-tune the rolling process for their particular material types.

Davi Inc. continues to invest heavily in research and development to develop new solutions in plate roll and angle roll machinery.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

The new alignment tool is ideal for use with boiler- and single tube high-temperature and high-pressure applications and sets up fast.

The new UNITOWER CNC from KASTO is designed specifically for automated feeding of CNC metal-cutting machines and as a buffer storage unit.

Davi Inc.’s iVision laser radius measuring system for its e-POWER fully electric machines provides a solution to the skilled labor shortage through unmanned operation capability.