Plasma Cutting Systems

This technology forces oxygen, nitrogen, argon, or even shop air through a small nozzle orifice inside a torch to create a high pressured gas flow, then introduces an electric arc started from an external power supply to generate an extremely high temperature plasma arc that can quickly pierce through a very wide range of electrically conductive alloys, including plain carbon and stainless steels, aluminum and its alloys, nickel alloys and titanium, and blow away any molten material. Because the cost of a plasma torch is low, traditional systems fit several torches to a cutting table and move the torches while the sheet of material being cut is held stationary.

Advancements in Cutting Systems Transform the Manufacturing Landscape

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

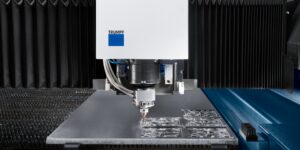

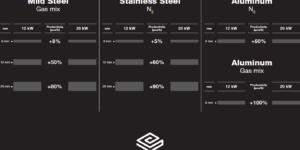

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

Variable beam shaping fiber laser technology, and the redesign of automation solutions to better handle part sorting are among the advances that position Mazak Optonics for the future.

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

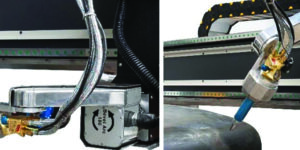

With the new BevelArc 3D, users can perform continuous beveling by tilting, without unnecessary torch turning.

Automated deburring line frees up employees at Liebherr-Werk Biberach GmbH from monotonous and physically demanding work. Machine aids the production of high-quality tower cranes and mobile construction cranes.

THOR F integrates plasma and oxyfuel cutting with an optional beveling system, and an optional tube and profile lathe. It also combines plate cutting with edge preparation and numerous mechanical machining operations, including milling, drilling, tapping, countersinking, marking, etc.