Part Marking Equipment

High-speed, Highly Efficient Marking Products Provide Sizeable Cost Savings

Make certain your products are marked with devices and systems that ensure reliable and dependable part traceability.

Make certain your products are marked with devices and systems that ensure reliable and dependable part traceability.

Leaders in metal forming and fabricating industry technologies continue to improve their products, resulting in increases to your productivity and the bottom line.

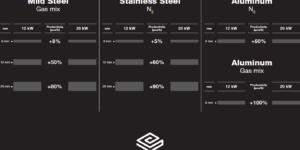

The Freedom to Innovate: TRUMPF Inc. Assists Customers in Realizing Their Greatest Projects

With VideoThe embodiment of TRUMPF is the ability to integrate its high-quality machine tools with its high-quality lasers to build machines that enhance their customers’ competitiveness.

Discover the latest advances in marking systems.

Demands are growing for sheet metal fabricators to mark their parts during production for product traceability in the field and better efficiencies in the shop, but many part identification systems can add an unnecessary secondary process. Whenever possible, consider finding ways to incorporate part marking into a manufacturing step that is already required. Here are some ways to use the equipment that you already have.

The Patmark 2080 is a lightweight handheld, portable, & battery operated dot pin marker from MB Metal Technologies.

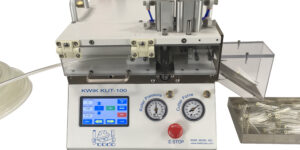

Simple to operate and understand, the Kwik Kut from Kwik Mark transforms manual cutting tasks into a streamlined process with enhanced accuracy, cut quality, and improved employee morale.

Kwik Mark Inc. Tag Master 3 uses dot peen technology to permanently mark industrial components.