Oxyfuel Cutting Systems

Highly cost efficient for cutting carbon steel, this thermal process uses oxygen and fuel gas (such as acetylene, propane, MAPP, propylene and natural gas) to cut through materials. The equipment is low cost, can be used manually or mechanized, and utilizes different fuel gas and nozzle designs to increase cut quality and cutting speed.

Advancements in Cutting Systems Transform the Manufacturing Landscape

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

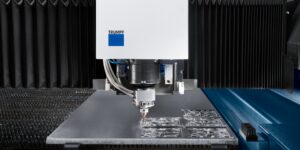

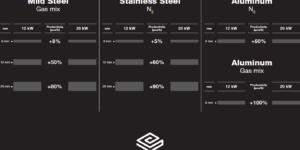

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

Variable beam shaping fiber laser technology, and the redesign of automation solutions to better handle part sorting are among the advances that position Mazak Optonics for the future.

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

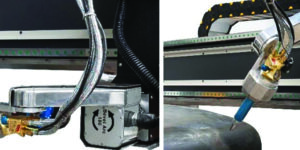

With the new BevelArc 3D, users can perform continuous beveling by tilting, without unnecessary torch turning.

THOR F integrates plasma and oxyfuel cutting with an optional beveling system, and an optional tube and profile lathe. It also combines plate cutting with edge preparation and numerous mechanical machining operations, including milling, drilling, tapping, countersinking, marking, etc.

Perform Perfect Hole Cutting, Increase Throughput, and Perform Fewer Secondary Finishing Operations

With VideoHGG’s new SPC 1500-3000 PT/VC cutting machine provides a clean operation using plasma or oxyfuel to perform the programmed cuts and is capable of ink, punch, and plasma marking depending on the application.