Machine Controls

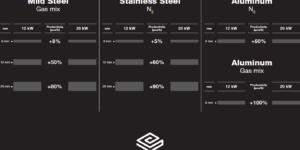

Increase Your Productivity with Highly Precise and Accurate Solutions

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

Servo Products’ Orion CNC retrofit package helps gives job shops an affordable alternative to replacing a whole milling machine. By replacing or adding controls, low- to mid-volume operations can reduce downtime and jack up profit margins.

Every extra part wrung from the same piece of raw and remnant material is money in your pocket. Here’s how to significantly increase earnings.

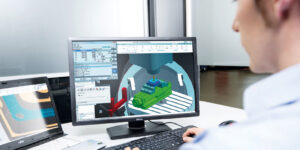

Across the emerging Smart Factory, connected systems are networking production processes from design to final delivery. Conversational programming makes it quick and easy for operators to generate programs at the machine, while other connected systems exchange and use information about tool management, batch processing/scheduling, machine monitoring, quality assurance and more.

Across the emerging Smart Factory, connected systems are networking production processes from design to final delivery. Conversational programming makes it quick and easy for operators to generate programs at the machine, while other connected systems exchange and use information about tool management, batch processing/scheduling, machine monitoring, quality assurance and more.

Siemens Brings Its Portfolio of Solutions to the Fabrication and Additive Manufacturing Sectors

With VideoSiemens is presenting its full portfolio of machine control hardware, software and cloud-based services to the fabrication industry

The M8 Series CNC now offers an Oscillation Cutting Option called Vibration Cutting Control, allowing for CNC lathes and mills to eliminate buildup of metal strands thus reducing obstructions in the tool path while machining parts.

All new Series GT products are completely cross-compatible with the discontinued Series B products, all while keeping the same mounting and assembly dimensions and specifications, as well as part numbers and list prices.