Laser Cutting Systems

These machines use either gas laser (CO2) or solid-state laser (YAG, disc and fiber) technology to generate a focused, precise pulsed laser beam or continuous wave laser beam that pierces through a wide variety of materials in flat sheet, tube, channel or structural shapes, then essentially melts the material away as it follows a programmed path for rapidly cutting holes, shapes and fine features, marking and engraving, leaving a highly accurate and smooth finish.

AI-powered Tools: Analyze and Adapt in Real Time and Improve Outcomes

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

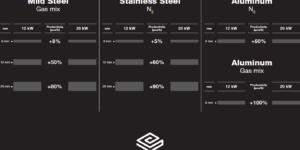

Savvy fabrication shops carefully evaluate ways tube and sheet laser machines can add value to the overall process rather than shooting straight to the highest laser power.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

The latest laser and fabrication technology will be showcased at IMTS 2024.

TRUMPF experts monitor TruLaser Center machinery during unattended operation; this live support for automated laser cutting helps night shifts run smoothly. The result is higher productivity from increased uptime.

Prima Power, a leader in sheet metal working manufacturing solutions, has introduced the latest addition to its 2D laser technology portfolio: the Platino Linear. It is an ideal investment for efficient, sustainable and advanced production.

TRUMPF’s new TruTool TSC 200 slat cleaner creates simpler, more efficient and ergonomic approach to removing slag. It can be used with all standard laser-cutting machines.