Cut-To-Length Lines

A cut-to-length (CTL) or a blanking line unrolls and flattens a coil of material, cuts it into sheets of precise lengths and stacks those sheets into a bundle. Functions can include, but not be limited to, coil stocking and coil loading, uncoiling and coil opening, straightening of the leading edge of the coil, edge trimming, scrap balling, scrap cutting, and sheet stacking. In-line equipment used in a system can vary according to the width, thickness and incoming coil weight and may include coil storage, uncoiler and coil loading, leveler, flattener, dust collector, grip, roll feeds, shears, laser cutting system, sheet stacker and related tooling and accessories.

Advancements in Cutting Systems Transform the Manufacturing Landscape

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

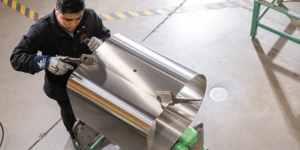

Davi’s advanced HMI controls allow shops such as AlumiTank to easily edit material libraries so they can further fine-tune the rolling process for their particular material types.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

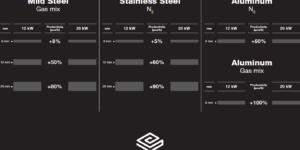

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

There is a direct relationship between laser machining and texturing capabilities and the manufacturing market’s demand for it. The more capacity, effectiveness and efficiency the technology gains, the more ways it will be industrialized and integrated into everyday use.

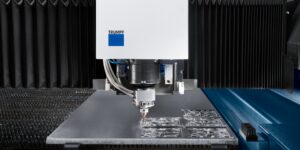

TRUMPF experts monitor TruLaser Center machinery during unattended operation; this live support for automated laser cutting helps night shifts run smoothly. The result is higher productivity from increased uptime.

Prima Power, a leader in sheet metal working manufacturing solutions, has introduced the latest addition to its 2D laser technology portfolio: the Platino Linear. It is an ideal investment for efficient, sustainable and advanced production.

A new flatsheet laser machine from TRUMPF, the TruLaser Series 3000 Bevel Cut Edition, prepares parts for welding while cutting. The machine automatically creates bevels on parts, and the solution is suitable for medium to thick sheet material and enables a wide range of edge geometries.