Coil Handling Equipment

A coil stock handling system stores, loads, positions, uncoils, straightens and feeds material of various sizes and weights into the tooling of a press production line. Depending on the product parameters and requirements of the production line, this system can include individual or integrated coil cradles, coil lifts, coil holding arms, upenders, uncoiling machines, servo feeds/electric feeds, air feeds, coil reels/stock reels, straighteners, feeding lines, cut-to-length operations, washers and lubricators, and other related equipment and tools.

Faster Cycle Times and Consistent Output Empower Fab Shops

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

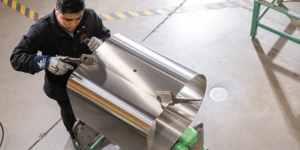

Davi’s advanced HMI controls allow shops such as AlumiTank to easily edit material libraries so they can further fine-tune the rolling process for their particular material types.

Davi Inc. continues to invest heavily in research and development to develop new solutions in plate roll and angle roll machinery.

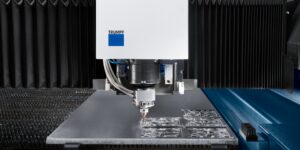

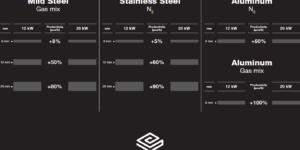

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

The advent of turnkey and completely integrated coil-fed laser processing systems promises to enable serious reductions in part costs.

The new UNITOWER CNC from KASTO is designed specifically for automated feeding of CNC metal-cutting machines and as a buffer storage unit.

Davi Inc.’s iVision laser radius measuring system for its e-POWER fully electric machines provides a solution to the skilled labor shortage through unmanned operation capability.

COVAL SAS’ CTE cup series has a large deflection capability, adapting easily to gripping flat, convex, or angular sheet metal.