CAD/CAM Software

Computer-aided design (CAD) software and computer-aided manufacturing (CAM) software is used to design and manufacture prototype parts, finished products, and production runs. An integrated CAD/CAM system uses CAD software to design models and assemblies of a product and interface with CAM software that references and applies those models and assemblies created in the CAD software to program specific manufacturing processes, perform functional simulation that optimizes each process step, then drive the machine tools used to produce physical parts from the product designs.

Faster Cycle Times and Consistent Output Empower Fab Shops

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

The productivity and efficiencies unleashed by AI tools overcome the skepticism that tends to take hold when it comes to using new tech in the slow to adapt manufacturing sector.

Your shop will be prepared for the challenges and opportunities in the coming year and beyond by integrating preventative maintenance into broader digital transformation initiatives.

When you move past the hype surrounding the promise of AI you will find it truly delivers real value to your shop. Before diving in, make sure AI is the right tool to fix your challenges.

The new UNITOWER CNC from KASTO is designed specifically for automated feeding of CNC metal-cutting machines and as a buffer storage unit.

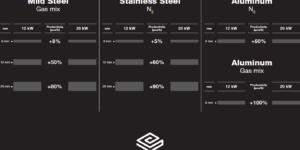

New to the North American market, TRUMPF’s TruMatic 5000 boosts productivity and part quality while reducing energy consumption. It also offers fully automated material flow thanks to new the SheetMaster.

THOR F integrates plasma and oxyfuel cutting with an optional beveling system, and an optional tube and profile lathe. It also combines plate cutting with edge preparation and numerous mechanical machining operations, including milling, drilling, tapping, countersinking, marking, etc.