Additive Manufacturing Systems

The process of joining materials to make parts from 3D model data, usually layer upon layer, using digital manufacturing technologies that include powder bed fusion, binder jetting (3D printing), material jetting, sheet lamination, material extrusion, directed energy deposition, and VAT polymerization.

Faster Cycle Times and Consistent Output Empower Fab Shops

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

Many industries, including motorsports, aerospace, defense, and semiconductors, are replacing aluminum–magnesium-silicon alloys, such as F357 and AlSi10Mg, with Aheadd® CP1 for a number of compelling reasons.

Additive Manufacturing Solutions will be displayed at Fabtech in Orlando.

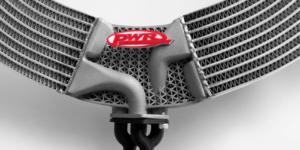

By embracing hybrid approaches to 3D metal printing, manufacturers can achieve greater efficiency, reduce waste, and create parts that were previously impossible to produce.

Velo3D’s Flow Developer: From black box to full transparency and control, the new product enables a pathway to migrate additive manufacturing knowledge to VELO3D’s fully integrated solution and print process optimization.

Mantle, the leader in metal 3D printing technology for toolmaking, unveils new tooling applications and customers.

The extensive expertise in Additive Manufacturing processes at Il Sentiero International Campus (an Industrial Research Centre established by Ecor International and based in Schio, Magreta, and Modena) empowers Ecor International to stand out among the Veneto and Italian aerospace industry…