Metal Forming & Fabricating

Material forming through stamping, notching, punching, bending, shearing, drawing and more using machinery such as mechanical presses, hydraulic presses, punch presses, turret punch presses, press brakes, shears, hydroforming machines, cold forming machines, hot forming machines and other equipment assisted by Computer Aided Design (CAD), Computer Aided Manufacturing (CAM), Computer Numerical Control (CNC), automation and robotics.

Faster Cycle Times and Consistent Output Empower Fab Shops

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

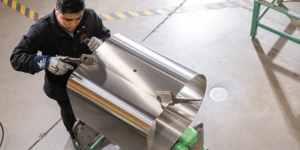

Davi’s advanced HMI controls allow shops such as AlumiTank to easily edit material libraries so they can further fine-tune the rolling process for their particular material types.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Robotic deburring and finishing solutions replace tedious manual processes, with precision.

Variations in machinery allow users to create unique designs and applications to support the emerging small tube segment.

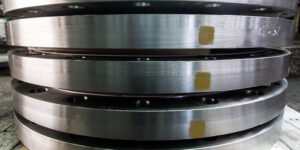

Forging Ahead: Speedy Delivery of High Quality, Open Die Forgings, Seamless and Contoured Rolled Rings and Complex Forged Parts

With VideoSpecialty forgers can manufacture custom, high-quality, seamless rolled rings in a variety of materials and finishes in as little as eight weeks.

Bega Special Tools’ MF Quick-Heater 3.0-3.5 kW, which weighs less than 8 kg, can be used for mounting, dismounting and pre-heating purposes.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

A Triform model 3696-10 fluid cell sheet hydroforming press was recently delivered to a major aerospace supplier in the U.K.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

The Importance of Effective Cleaning and Choosing the Right Method for Parts Manufacturing

With VideoSuccessfully plan for your shop’s cleaning processes, including the addition of new systems and fluids, by making it part of your primary decision making.

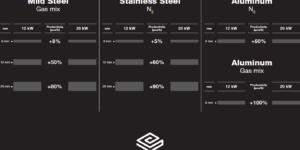

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Make certain your products are marked with devices and systems that ensure reliable and dependable part traceability.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

Due to their flexibility, precision, edge finishes, eco-friendliness and more, waterjet systems are gaining popularity as one of the top technologies for cutting.