Vertical Machining Centers

Economically priced and ideal for both small job shops and larger machining operations, vertical machining centers (VMCs) use vertically-oriented spindles with tools that stick straight down from the tool holder to approach workpieces mounted on a table for machining operations that cut across the surfaces of a workpiece.

Increase Uptime: Fewer Unexpected Failures Mean More Time for Production

Resilient and transparent maintenance scheduling provides actionable data to maintain an agile and responsive shop.

Resilient and transparent maintenance scheduling provides actionable data to maintain an agile and responsive shop.

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

The versatility and single setup functionality of multi-axis machines supports faster machining cycles with reductions in downtime.

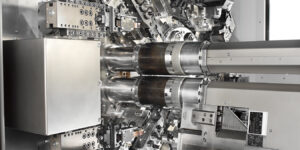

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Automated solutions and other advances on machining centers increase flexibility and productivity within your processes.

With EMAG’s new machine a finished ball pin leaves the machine every seven seconds with each component undergoing an exceptionally comprehensive measurement.

Mazak advances machine connectivity with its new SmartBox 2.0, which offers enhanced productivity and security, ensuring safe data export from machines to factory networks.

MicroX ULTRA: Industry-first micro tool grinding using nanometer resolution down to D0.03mm

With VideoANCA’s newest ULTRA machine makes micro tool grinding easier, more precise and more productive as the only nano-level resolution micro tool grinder.