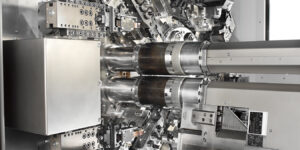

Turning Centers

A turning center is a lathe with a computer numerical control (CNC) that is used to make cylindrical parts by moving the cutting tool across a rotating workpiece to reduce the diameter of the workpiece to a specified dimension and produce a smooth part finish. The CNC can transmit and manage cylindrical transformations primarily used for turning and effectively control a live tooling spindle on the turret that functions as a rotary, contouring axis to perform a variety of milling and drilling operations.

How to Prepare Your CNC Machines and Robots for Optimal Performance Post-Shutdown

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

The versatility and single setup functionality of multi-axis machines supports faster machining cycles with reductions in downtime.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Overcome labor and productivity challenges with turning centers and lathes that are created to increase the efficiency of your processes.

Expanded efficiencies built into turning centers and lathes result in productivity increases for shops of all sizes.

Palmgren’s bench lathe meets the requirements of prototype shops, home machinists, jewelry manufacturing, tool rooms and fabrication and maintenance shops which need to turn small metal parts.

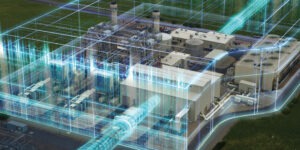

Advanced, Real-time, Cyber-attack Response Limits the Impact Within Milliseconds at Machine Speed

With VideoSIBERprotec from Siemens delivers automatic cyber response solution for industrial OT systems.

GibbsCAM announces the release of GibbsCAM 2024, which continues to boost end-user productivity for programming advanced machining centers, underpinning the GibbsCAM promise of Powerfully Simple, Simply Powerful.