Multitasking Machines

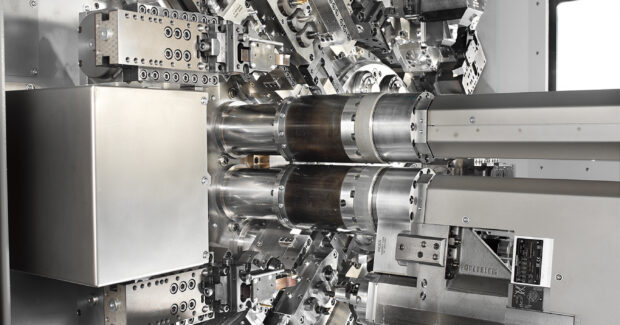

To help shops react quicker and more flexibly to market demands for increasingly complex parts in smaller batch sizes, multi-tasking machines use a single setup to perform different metalworking operations that completely process a part of raw material into a desired final shape and size without manual intervention. This improves part quality, accelerates manufacturing and directly impacts shop capacity, floor space, personnel and profitability.

Versatile Turning Center Solutions Ensure Your Shop Stays Competitive

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

High-end tap producers are enhancing designs to meet the escalating market share of specialized materials required by high-tech industries, which calls for customized and tailored designs.

Power skiving has revolutionized the gear manufacturing industry by enabling the production of high-precision gears with complex geometries.

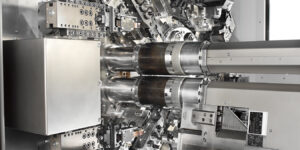

The speed, versatility, flexibility and precision of multi-axis machines supports a wide range of industries and part sizes.

Different types of CNC machines will appear in smart factories. Here’s what you need to know about upgrading and updating your machines.

With EMAG’s new machine a finished ball pin leaves the machine every seven seconds with each component undergoing an exceptionally comprehensive measurement.

Adding TRU TECH’s product line extends Star Cutter’s offering of 5-axis, broach, cylindrical and centerless grinders.

Mazak advances machine connectivity with its new SmartBox 2.0, which offers enhanced productivity and security, ensuring safe data export from machines to factory networks.