Milling Machines

A milling machine uses a horizontal arbor or vertical spindle to rotate a cutting tool above a horizontal table that moves a clamped and stationary workpiece using feed motion transmitted from the machine tool. The cutting tool shaves off and removes small sections of material from the surfaces of the workpiece until its final machined specifications are produced. For example, face milling creates a flat surface on the workpiece, periphery milling generates a primary surface parallel to the spindle rotation, and slot milling produces a slot or channel in the workpiece.

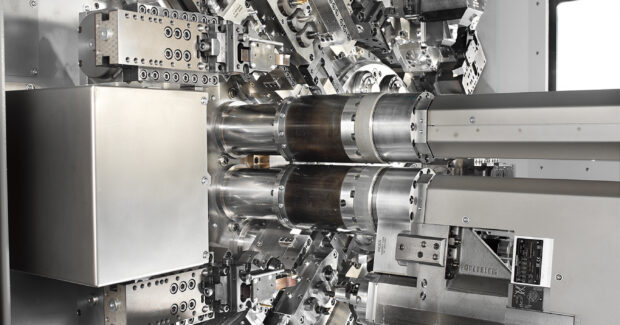

Versatile Turning Center Solutions Ensure Your Shop Stays Competitive

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

The speed, versatility, flexibility and precision of multi-axis machines supports a wide range of industries and part sizes.

Expanded efficiencies built into turning centers and lathes result in productivity increases for shops of all sizes.

Shops rely on the latest technologies to make it faster, better, cheaper.

Circular machining with low radial engagement and constant feed per tooth extends tool life by minimizing heat and vibration when machining extremely hard materials. CAM and control developers are making it easier for any size shop to add this technique to their capabilities.

Mazak advances machine connectivity with its new SmartBox 2.0, which offers enhanced productivity and security, ensuring safe data export from machines to factory networks.

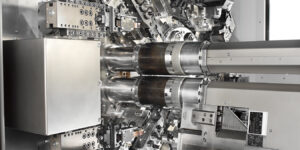

Eight machines plus the newest ANCA Integrated Manufacturing System (AIMS) to be featured in Booth 237406, as the company celebrates its 50th anniversary and the opening of its LA Tech Center

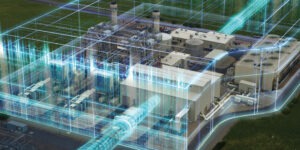

Advanced, Real-time, Cyber-attack Response Limits the Impact Within Milliseconds at Machine Speed

With VideoSIBERprotec from Siemens delivers automatic cyber response solution for industrial OT systems.