Lathes

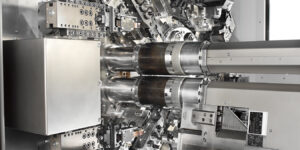

A lathe is a basic two-axis machine tool that consists of a headstock with spindle, a chuck for holding the part, a lathe bed, carriage and cross-slide, tool turret and tailstock. The workpiece is loaded into the chuck and rotated while a cutting tool moves across it for specific cutting, sanding, knurling, drilling, contouring, facing and other turning operations.

How to Prepare Your CNC Machines and Robots for Optimal Performance Post-Shutdown

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Shops collaborate with tool manufacturers to successfully achieve efficient machining of a wide range of materials.

The International Manufacturing Technology Show (IMTS) will take place September 12-17 at McCormick Place in Chicago. Here is a sneak peek as to what exhibitors’ plan to showcase.

San Francisco-based Plethora Corp. shaves as much time as possible from the iterative design process. After developing software that enables customers to design for the shop’s capabilities in real time, this 2017 start-up delivers prototypes and production runs within three days.

Palmgren’s bench lathe meets the requirements of prototype shops, home machinists, jewelry manufacturing, tool rooms and fabrication and maintenance shops which need to turn small metal parts.

GibbsCAM announces the release of GibbsCAM 2024, which continues to boost end-user productivity for programming advanced machining centers, underpinning the GibbsCAM promise of Powerfully Simple, Simply Powerful.

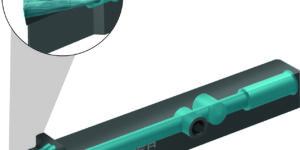

The Walter Turn SCLC-S-P/SDJC-S-P/SVJB-S-P tool holders supply precision cooling on the rake face and clearance face.