Horizontal Machining Centers

Ideal for automation and uninterrupted, unattended production operations, a horizontal machining center (HMC) uses a horizontally-oriented spindle, parallel to the ground floor, with tools that stick out of the side of the toolholder and cut across the surfaces of a workpiece, allowing chips to fall away without having to be cleared from the table. A two-pallet workchanger used with an HMC saves time because work can be loaded on one pallet while machining takes place on the other pallet.

Versatile Turning Center Solutions Ensure Your Shop Stays Competitive

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

High-end tap producers are enhancing designs to meet the escalating market share of specialized materials required by high-tech industries, which calls for customized and tailored designs.

Automated solutions and other advances on machining centers increase flexibility and productivity within your processes.

Different types of CNC machines will appear in smart factories. Here’s what you need to know about upgrading and updating your machines.

Shops collaborate with tool manufacturers to successfully achieve efficient machining of a wide range of materials.

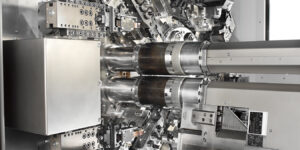

With EMAG’s new machine a finished ball pin leaves the machine every seven seconds with each component undergoing an exceptionally comprehensive measurement.

Mazak advances machine connectivity with its new SmartBox 2.0, which offers enhanced productivity and security, ensuring safe data export from machines to factory networks.

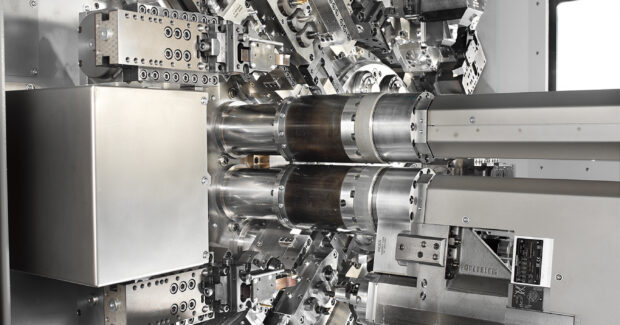

MicroX ULTRA: Industry-first micro tool grinding using nanometer resolution down to D0.03mm

With VideoANCA’s newest ULTRA machine makes micro tool grinding easier, more precise and more productive as the only nano-level resolution micro tool grinder.