Grinding Machines

To make precision cuts that produce very fine finishes, a grinding machine removes material from a workpiece by abrasion, using a power-driven grinding wheel as a cutting tool spinning at a required speed determined by wheel diameter and manufacturer’s rating, along with a bed-mounted fixture to guide and hold the workpiece. The grinding head can be controlled to travel across the fixed workpiece, or the workpiece can move while the grinding head remains in a fixed position. Types of precision grinding operations include centerless grinding, cylindrical grinding, form grinding, surface grinding and more.

Versatile Turning Center Solutions Ensure Your Shop Stays Competitive

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

IMTS 2024 will feature abrasive machining, sawing and finishing.

High-end tap producers are enhancing designs to meet the escalating market share of specialized materials required by high-tech industries, which calls for customized and tailored designs.

The speed, versatility, flexibility and precision of multi-axis machines supports a wide range of industries and part sizes.

Different types of CNC machines will appear in smart factories. Here’s what you need to know about upgrading and updating your machines.

Adding TRU TECH’s product line extends Star Cutter’s offering of 5-axis, broach, cylindrical and centerless grinders.

The new process helps significantly reduce lead time and improve quality for customers.

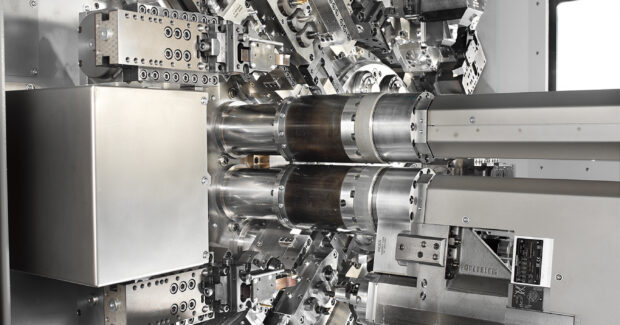

MicroX ULTRA: Industry-first micro tool grinding using nanometer resolution down to D0.03mm

With VideoANCA’s newest ULTRA machine makes micro tool grinding easier, more precise and more productive as the only nano-level resolution micro tool grinder.