Gear Cutting Machines

Gear cutting machine tools adjust and control cutting speeds for precision production of a specific number of gear teeth, including the milling of circular, holed plates without teeth, hobbing or cutting out of teeth, broaching or boring through inner surface machining, quenching by heat treatment and grinding of the surfaces and the teeth.

How to Prepare Your CNC Machines and Robots for Optimal Performance Post-Shutdown

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

Effectively planning a post-shutdown maintenance procedure and power up program will ensure a smooth transition from maintenance to production.

See the latest gear technology at IMTS 2024.

Power skiving has revolutionized the gear manufacturing industry by enabling the production of high-precision gears with complex geometries.

The speed, versatility, flexibility and precision of multi-axis machines supports a wide range of industries and part sizes.

Innovative tools and equipment are available to support today’s gear manufacturing processes and keep the wheels of production spinning.

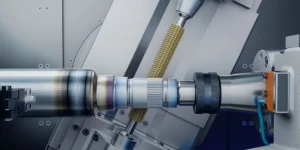

This peel grinding solutions on ANCA’s MX7 platform significantly reduces cycle time while boosting productivity.

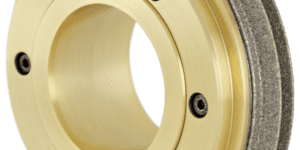

Adding TRU TECH’s product line extends Star Cutter’s offering of 5-axis, broach, cylindrical and centerless grinders.

While many other machine manufacturers outsource software development, resulting in long and costly development cycles, the in-house experts at Affolter react to each and every customer request individually and promptly.