Drilling Machines

From small handheld power drills to bench-mounted and floor-mounted drill presses, drilling machines cut holes and do tapping, countersinking, reaming, boring and counterboring into or through metal, wood, or other materials using a cutting tool held in the drill by a chuck or Morse taper that is rotated and fed into the work at variable speeds.

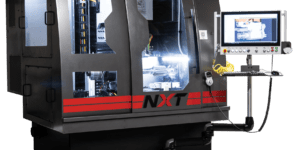

Versatile Turning Center Solutions Ensure Your Shop Stays Competitive

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

The speed, versatility, flexibility and precision of multi-axis machines supports a wide range of industries and part sizes.

Different types of CNC machines will appear in smart factories. Here’s what you need to know about upgrading and updating your machines.

Exhibitors will showcase the latest in grinding technologies, sawing and cutoff machines, as well as a variety of finishing technologies.

A heavy equipment manufacturer is using a 6-axis robotic arm equipped with a drilling spindle to very precisely make holes in structural steel up to 1 inch thick. The solution is one-third the cost of traditional drilling but performs many other applications and requires just one operator.

Mazak advances machine connectivity with its new SmartBox 2.0, which offers enhanced productivity and security, ensuring safe data export from machines to factory networks.

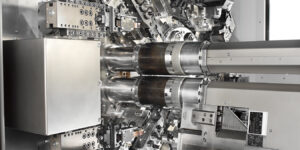

Eight machines plus the newest ANCA Integrated Manufacturing System (AIMS) to be featured in Booth 237406, as the company celebrates its 50th anniversary and the opening of its LA Tech Center

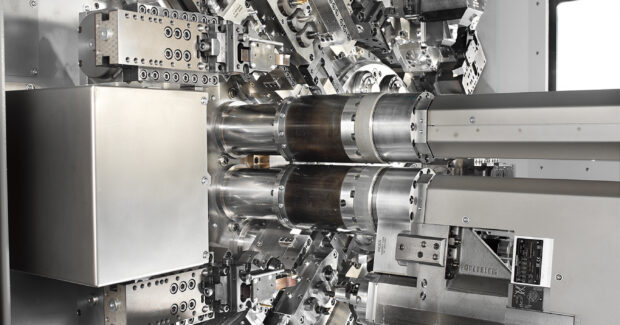

UNISIG’s R-4-2-2 fully automated barrel cell provides continuous and synchronous production. Automation such as robots and conveyors can be machine mounted or used to combine multiple machines or operations.