CAD/CAM Software

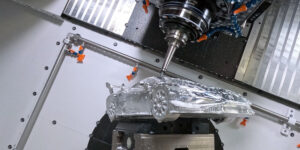

Computer-aided design (CAD) software and computer-aided manufacturing (CAM) software is used to design and manufacture prototype parts, finished products, and production runs. An integrated CAD/CAM system uses CAD software to design models and assemblies of a product and interface with CAM software that references and applies those models and assemblies created in the CAD software to program specific manufacturing processes, perform functional simulation that optimizes each process step, then drive the machine tools used to produce physical parts from the product designs.

AI-powered Tools: Analyze and Adapt in Real Time and Improve Outcomes

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

AI’s impact on manufacturing is profound. We are just scratching the surface of what will be possible.

The productivity and efficiencies unleashed by AI tools overcome the skepticism that tends to take hold when it comes to using new tech in the slow to adapt manufacturing sector.

Your shop will be prepared for the challenges and opportunities in the coming year and beyond by integrating preventative maintenance into broader digital transformation initiatives.

When you move past the hype surrounding the promise of AI you will find it truly delivers real value to your shop. Before diving in, make sure AI is the right tool to fix your challenges.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

Blaser Swisslube, in collaboration with its industry partners, demonstrates machining strategies for complex parts.

Adding TRU TECH’s product line extends Star Cutter’s offering of 5-axis, broach, cylindrical and centerless grinders.

MACHINUM accelerates digital transformation and sustainability for manufacturing operations by optimizing shop floor performance and productivity for industrial automation businesses