Machining

Material removal through cutting, turning, milling, drilling, grinding, tapping and more using machinery such as laser cutting systems, plasma cutting systems, oxyfuel cutting systems, milling machines, drill presses, lathes, horizontal machining centers, vertical machining centers, turning centers, multitasking machines, electrical discharge machines and other equipment assisted by Computer Aided Design (CAD), Computer Aided Manufacturing (CAM), Computer Numerical Control (CNC), automation and robotics.

Versatile Turning Center Solutions Ensure Your Shop Stays Competitive

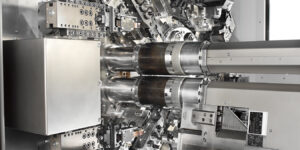

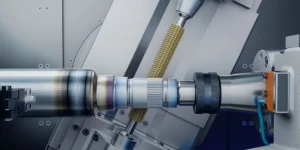

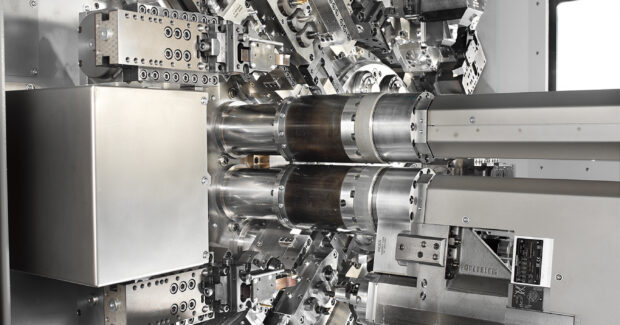

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

The release brings the benefits of CloudNC’s CAM Assist solution to more global users, including Siemens’ core customer base of major manufacturing corporations and machine shops supplying the aerospace, automotive, technology and energy sectors.

June manufacturing technology orders climbed 6.5 percent over May to $373.2 million.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

See the latest gear technology at IMTS 2024.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

New cloud-based laser-cutting quotation software from ipLaser typically more than halves the time and manual input required by laser-cutting companies to prepare precise estimates for industries using their services.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Siemens expands its SIMATIC MICRO-DRIVE with benefits such as seamless network integration, integrated drive safety, versatility, and easy installation and commissioning.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

High-end tap producers are enhancing designs to meet the escalating market share of specialized materials required by high-tech industries, which calls for customized and tailored designs.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

They add dedicated personnel to their service and customer support operations.

June manufacturing technology orders climbed 6.5 percent over May to $373.2 million.

The release brings the benefits of CloudNC’s CAM Assist solution to more global users, including Siemens’ core customer base of major manufacturing corporations and machine shops supplying the aerospace, automotive, technology and energy sectors.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Visitors to GF Machining Solutions’ booth will get a first glimpse of this next-gen wire EDM technology ahead of its global market launch later this year.