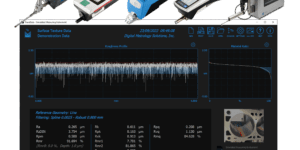

Surface Roughness/Finish

This category includes systems used to inspect the surface integrity of a workpiece after it has been processed by any surface modification process, including forming, metal cutting, welding, surface treatment, or other surface alteration. In the fabrication process, a surface’s roughness is a measurement of the height of irregularities and asperities on a finished surface after machining. ‘Finish’ is not a measurable quality, but depend on the viewer’s perception and the requirements of the task. Devices used to measure the roughness of a workpiece’s surface are called profilometers; manual comparison can also be made against a sample of a known surface roughness.

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Balancing tool assemblies set the stage for smooth machining that produces parts with consistent surface finish. Balancing also accelerates production because speeds and feeds can increase without compromising the part.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

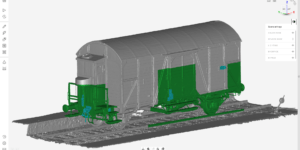

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

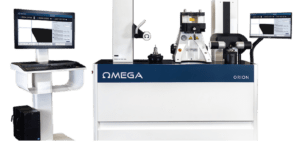

REGO-FIX partners with Omega TMM to create the ORION powered by REGO-FIX – a tool measuring machine using REGO-FIX’s powRgrip tool holding system with Omega TMM’s presetting technology.

One click in TraceBoss configures the gage, initiates a measurement, and presents the results and graphics full screen and in high resolution.

The handheld device now features a metal housing and readings are from atmospheric oxygen level (20.94%), down to 100 ppm (0.01%) of oxygen.