Software

This category includes any free-standing or integrated software systems used for measurement or inspection in the manufacturing process. Software is typically used to automate mechanical processes, analyze and rate the quality of cutting tools, integrate with probes and product inspection equipment to translate data into centralized system, program CMMs, laser scanners, and laser printers, generate inspection schedules and reports, support mobile and/or offline inspections, and a variety of other applications. Many software platforms are customized to specific tasks, or to the needs of their users.

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Balancing tool assemblies set the stage for smooth machining that produces parts with consistent surface finish. Balancing also accelerates production because speeds and feeds can increase without compromising the part.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

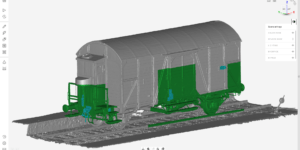

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Leading edge equipment, technologies and software provide a detailed look into the health and condition of cutting tools.

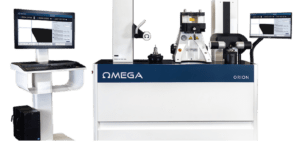

REGO-FIX partners with Omega TMM to create the ORION powered by REGO-FIX – a tool measuring machine using REGO-FIX’s powRgrip tool holding system with Omega TMM’s presetting technology.

Efficiency-optimizing enhancements unveiled by Evident Corp. on its MapROVER™ and SteerROVER™ corrosion and weld inspection scanners.

Volume Graphics 2024.1 helps users collaborate and evaluate product quality from CT and other non-destructive testing technologies.