Optical Measurement Equipment

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

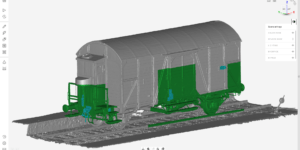

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Automated measurements of workpieces in machines are progressively more important in today’s manufacturing processes, resulting in shorter production times and fewer interruptions. What’s more, there is more confidence when it comes to the measurement process.

Exact Metrology worked with artist Tom Tsuchiya to create relief figures of the 1869 Cincinnati Reds team.

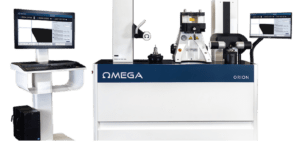

REGO-FIX partners with Omega TMM to create the ORION powered by REGO-FIX – a tool measuring machine using REGO-FIX’s powRgrip tool holding system with Omega TMM’s presetting technology.

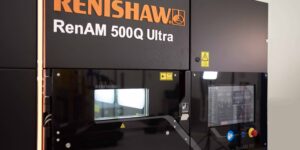

Renishaw’s patented TEMPUS technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring.

Automated Precision Inc. now offers Dynamic 9D LADAR mounted on an Autonomous Guided Vehicle for use in aerospace manufacturing inspections.