Go/No Go Gauges

Go/No go gauges are tools used to check the tolerances of a workpiece, for example, thread depth and major diameter of a screw. Go/no go gauges are utilized to ensure interchangeability of parts between processes. Go/no go gauges rate a component as either acceptable (within tolerance), or outside of tolerance. Examples of go/no go gauges include plug gauges (used like a plug to measure hole depth), pin gauges (used for measuring very small holes), and snap gauges (incorporates four jaws that allow for single-action checking of workpiece).

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

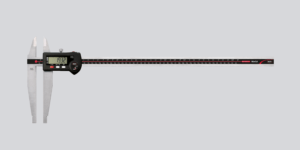

Mahr Inc.’s new MarCal 18 EWR(i) digital caliper features an expanded 800 mm measuring range and integrated wireless connectivity.

Mahr Inc. introduces the new MarSurf M 410, which provides high precision and accuracy for surface roughness measurements on small and large workpieces.

Mitutoyo America Corp. releases the new LH600F/FG Height Gage, which is the latest model in the Mitutoyo Linear Height Gage line, and which features several added features and benefits.