Dial Indicators

Dial indicators, or dial gauges, are mechanical display instruments used to provide a readout of some small measurement not immediately discernable to the naked eye. Common dial indicators incorporate a dial display with arms and graduations on a circular scale, similar to a clock face. Internally, dial indicators incorporate a rack and pinion gear to read its probe position. In machining, dial indicators can be used to inspect variations in tolerance of machined parts, beam, ring, or rod deflection from its axis, calibrate a machine, manufacture precision tools, centering a workpiece in a lathe, inspecting for lateral run-out of a rotor, and other small measurements.

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

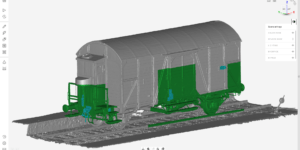

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

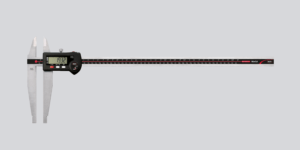

Mahr Inc.’s new MarCal 18 EWR(i) digital caliper features an expanded 800 mm measuring range and integrated wireless connectivity.

Mahr Inc. introduces the new MarSurf M 410, which provides high precision and accuracy for surface roughness measurements on small and large workpieces.

Mitutoyo America Corp. releases new versions of IDC and IDF series Digimatic indicators which include several new designs and functions.