Coordinate Measuring Machines

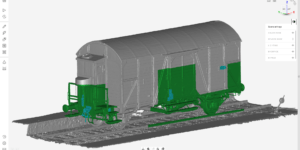

This category includes machines used to measure an object’s geometry through discrete surface point sensing via probe, commonly either a laser, optical probe, mechanical probe, or white light. Coordinate Measuring Machines (CMMs) can be calibrated to complete repeated measuring tasks automatically without reprogramming after each use. CMMs commonly use micrometer precision to track probe movement along three axes, producing a ‘point cloud’ mapping the object’s surface. CMMs are commonly used to test a machined part against its intended pattern for accuracy of manufacture.

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Balancing tool assemblies set the stage for smooth machining that produces parts with consistent surface finish. Balancing also accelerates production because speeds and feeds can increase without compromising the part.

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Improvements to coordinate measurement machines speed up the measuring process, and improve accuracy and repeatability.

CMMs provide precise measurements and shorter measurement times.

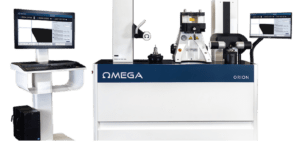

REGO-FIX partners with Omega TMM to create the ORION powered by REGO-FIX – a tool measuring machine using REGO-FIX’s powRgrip tool holding system with Omega TMM’s presetting technology.

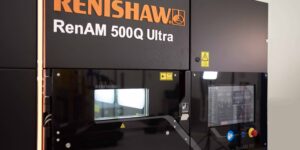

Renishaw’s patented TEMPUS technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring.

Automated Precision Inc. now offers Dynamic 9D LADAR mounted on an Autonomous Guided Vehicle for use in aerospace manufacturing inspections.