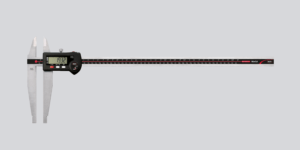

Calipers

Calipers are calibration tools used to measure the distance between two opposite sides of a workpiece, machine part, or other object related to the machining process. Common manual calipers feature sliding jaws that are adjusted to fit across two points to be measured, and then compared to a ruler or other measuring tool to get a reading. Inside calipers measure the internal size of an object; outside calipers measure the external size of an object, including large-diameter objects. Divider calipers, also called compasses, incorporate sharpened points that can scribe a line on the material. ‘Oddleg’ calipers incorporate a bent leg, allowing it to scribe a line at a set distance from a workpiece’s edge. Modern calipers such as Vernier, digital, dial, and micrometer calipers measure distances with extremely high accuracy.

Machined Metal Parts: Tips to Ease the Inspection Process

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

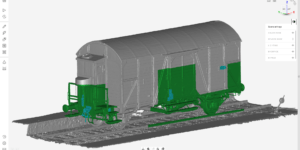

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Mahr Inc.’s new MarCal 18 EWR(i) digital caliper features an expanded 800 mm measuring range and integrated wireless connectivity.

DROs with absolute encoders from igaging and Mitutoyo allow you to read the position where you stop machining even when you turn the power off or lose power during a storm or electrical shut off.

Gefran introduces TWIIST, which features a unique helical magnetoelectronic design that allows it to take multiple measurements simultaneously, with a focus on operator safety.