Machine Tool Repair and Rebuilds

This category includes any tools or systems related to the repairing or rebuilding of machines and tools used in the fabricating and metalworking process. A ‘rebuild’ includes restoring a machine to its original mechanical specifications, during which each mechanical component is cleaned, inspected, repaired or replaced, and then rebuilt and recalibrated. Worn surfaces are scraped, bearings and seals are repaired or replaced, hydraulic and lubrication systems are rebuilt, exterior surfaces may be repainted, and machine geometric alignments are returned to Original Equipment Manufacturer (OEM) specifications.

Technical Service in the Era of Industry 4.0

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

The spindle is the heart of the machine tool. Its reliability is critical. Should it fail, remanufacturing can enable a practical, quick and cost-effective return to service and productivity.

Industry 4.0 technologies, particularly given their recent price drops, are already shaping up 2018 to be the year where VR, AI and other new and exciting technologies make their way onto the plant floor.

If a spindle breaks down, what is your shop’s plan of action? Is it the most practical and efficient way to deal with a down spindle?

By using borescopes from PCE Instruments, manufacturers can identify changes indicative of a machine fault and take corrective action prior to critical machine failure.

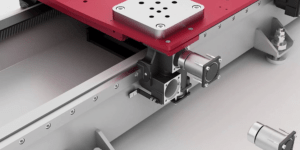

Güdel’s cam follower is a cylindrical roller bearing mounted on a stud that rides on the guide rail, providing significantly increased resilience to harsh industrial environments compared with traditional profile guides commonly used in 7th axis tracks.

EXAIR’s FloodStream liquid atomizing spray nozzle is manufactured from 303 stainless steel. Common applications include washing/wetting, dust suppression, lubrication, part cooling and more.

Force Control Industries’ Magnashear hazardous duty brakes meet hazardous classifications making them ideal for applications that require explosion-proof components.