Indoor Air Quality

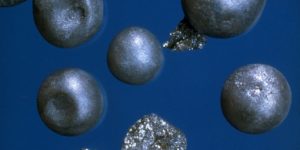

This category includes tools and systems used to filter or monitor the air quality in and around the buildings and structures used for fabricating and metalworking. Maintaining good indoor air quality (IAQ) is important to not only the health of operators, but can also impact product quality. Tools used to test IAQ collect air samples and samples of building surfaces, monitor exposure to pollutants, and computer model air flow inside buildings. Welding operations create hazardous pollutants that must be filtered or extracted to maintain good IAQ; this is done with filtration units at the point of origin, full-room ventilation systems, and air cleaners.

Hastings Air Energy Control Delivers on a “Mist” Opportunity for Detroit Edge Tool Co.

An ambient air cleaning solution eliminates persistent oil mist and saves money.

An ambient air cleaning solution eliminates persistent oil mist and saves money.

Harmful particulates in job shops pose risks to both your workers and your facility. Fortunately, there are versatile, durable, modular, more compact and customizable fume and dust collectors that improve indoor air quality by creating a safe environment and protecting your machinery and facility from fires, for example.

Get past the initial equipment and installation costs and start thinking about total cost of ownership over time, including direct operating costs such as energy use, filters and maintenance, and indirect costs such as equipment downtime. Here are five ways a small shop can maximize their clean air budget and get more out of their equipment in the long run.

How well are your dust collectors keeping up? If you’ve recently upgraded your laser cutting equipment or are experiencing unexplained equipment failures, now is the time to reevaluate your dust collection system. Investing in better dust control now will pay dividends in extended equipment life and better productivity for your laser cutting machines.

Job shops and other metalworking facilities affected by this standard must comply with most of the requirements by March 12, 2018 – they have less than two years to provide any required change rooms and showers and three years to implement engineering controls. Here’s why dust, mist and fume collectors are the best strategy to protect workers from the devastating pulmonary diseases associated with beryllium exposure.

The typical applications for HEMCO’s EnviroMax Laminar Flow Enclosures include liquid handling stations, compounding, high throughput screening, sample weighing, powder handling and HPLC equipment.

EXAIR’s new 316 Stainless Steel ATEX Cabinet Cooler Systems have cooling capacities up to 5,600 Btu/Hr., and are an ideal answer for protecting electrical enclosures with problematic overheating in areas with explosive atmospheres, both indoors and outdoors.

The ModuLab can achieve strict environmental control by incorporating HEPA filtration to regulate air quality ranging from Class 1,000 to 100,000.