September 2024

Digital Issue

Build a Resilient Workforce: How do metalworking manufacturers generate value through training efforts to optimize their existing workforces, as well as new hires? Today, workforce training efforts using the latest technologies such as digitalization, automation and AI lead to an increase in productivity and quality, as well as foster a culture of continuous improvement and innovation, according to one of the article's interviewees. For example, training through virtual reality addresses safety concerns, such as when using abrasives, where trainees can learn from making mistakes and correcting them in virtual settings so they can be successful (and safe) once they are in an actual shop setting. These types of programs can address specific skill gaps and reduce downtime in a tight labor market, which equals increased efficiency and competitiveness.

Subscribe View Digital IssueMetalworking industries achieve superior productivity and product quality by utilizing advanced, streamlined solutions.

Proper filter selection and care will help you reduce operating costs and maintain a clean, healthy environment for workers.

While utilizing digital platforms and technologies such as virtual reality for workforce training are powerful tools, there is no substitute for hands-on training.

The integration of AI, machine learning, and automation in tube and pipe fabrication signifies a major leap forward in manufacturing technology.

Enterprise-software provider Epicor develops user-friendly, cognitive tools and data that empowers manufacturers to make informed decisions at the right time.

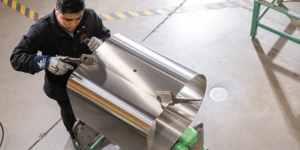

Davi’s advanced HMI controls allow shops such as AlumiTank to easily edit material libraries so they can further fine-tune the rolling process for their particular material types.

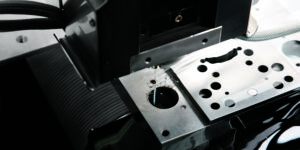

EDM generators categorized as “intelligent” are digital and monitor every single spark while working in unison with today’s adaptive control human machine interfaces that increase machine productivity.

Enterprise-software provider Epicor develops user-friendly, cognitive tools and data that empowers manufacturers to make informed decisions at the right time.

Faster machining centers and processes decrease overall production time, enabling your shop to gain improved market responsiveness.

Boring bars, end mills, reamers, indexable drills — there are a myriad of tooling options when opening or enlarging existing holes, but which should you choose for your application? When opening an existing hole, you are often faced with three…

Engineered for exceptional accuracy and safety, fixturing systems and welding tables are invaluable for both small-scale and industrial welding operations.

How technology is transforming training, learning and work in manual welding, cobots and automated systems.

Power generation packager adds ESAB cobot, updates WPS from TIG to MIG and increases production five-fold for a critical part.

Metalworking shops can ensure consistent quality and reduce errors by embracing innovative gauging solutions and adhering to best practices.

Create and follow effective preventative maintenance checklists for use during mandatory shutdowns.

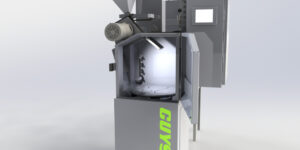

An ambient air cleaning solution eliminates persistent oil mist and saves money.

Proper filter selection and care will help you reduce operating costs and maintain a clean, healthy environment for workers.

Protecting workers and maintaining a safe working environment with the newest, state-of-the-art personal safety gear and ergonomic protection will continue to play an essential role in lowering the number of workplace injuries, as well as enhance overall safety throughout the…

An ambient air cleaning solution eliminates persistent oil mist and saves money.

While tapping may seem simple on the surface, there are many potential pitfalls related to tooling, operating parameters and quality assurance practices.

The latest advancements in cutting tools; end mills, thread mills, thread formers and inserts, are transforming the machining industry.

With a mission to develop a next-generation bit design, Salvation Drilling Tools enlisted Sandvik Coromant and its advanced machining knowledge to help pioneer a new three-cone rotary rock bit.

The latest advancements in gauges, instrumentation, and measurement solutions are transforming the landscape of precision measurement and inspection.