November/December 2024

Digital Issue

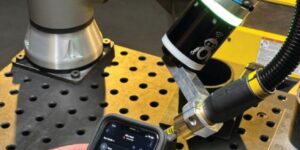

Welding Technology: Robotics, Automation & Cobots: Cobots are increasingly intuitive — if you can create a song playlist you can program a weld sequence using an app on a mobile device, for example. What started as an ideal solution for high-mix, low-volume work has evolved to major shifts such as supporting the acceleration in the adoption of laser welding; portability — bringing the cobot to the work such as welding three-story construction equipment, and in shipbuilding, and; the addition of coordinated motion to significantly optimize cycle times and follow precise toolpaths.Cobot manufacturers, integrators, and welding equipment manufacturers continue to improve on cobot technologies to overcome the ongoing skilled welder shortage — 82,500 welding jobs need to be filled annually between now and 2028.

Subscribe View Digital IssueTool cabinets and material storage systems enhance operations by providing smart, secure, and easily adjustable tool and material storage.

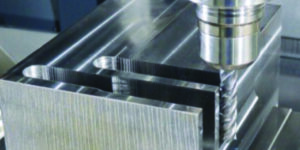

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Balancing tool assemblies set the stage for smooth machining that produces parts with consistent surface finish. Balancing also accelerates production because speeds and feeds can increase without compromising the part.

By embedding safety into the core of your operations, you’re not just preparing for the next OSHA mandate — you’re preparing your business for every possible change that comes down the pipeline.

Faster cutting speeds, and advances in software and automation capabilities expand the versatility of metal cutting systems.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

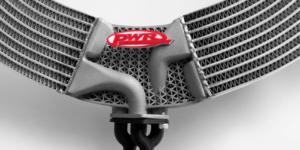

Many industries, including motorsports, aerospace, defense, and semiconductors, are replacing aluminum–magnesium-silicon alloys, such as F357 and AlSi10Mg, with Aheadd® CP1 for a number of compelling reasons.

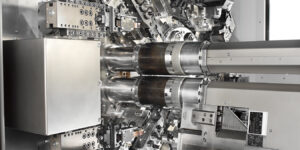

Innovations in turning centers and lathes reduce set up times allowing you to produce more complex parts in shorter time frames.

Modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Airgas enables your fabrication operation to “fill your potential.”

How IIoT can improve efficiency, quality and safety.

Automation, cobots and robots facilitate resilience and provide numerous competitive advantages to the metalworking industry.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

Cutting-edge real time visioning systems and advancements in cobot welding ensure precision, reproducibility, and controlled and reliable production.

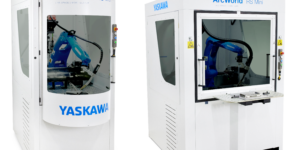

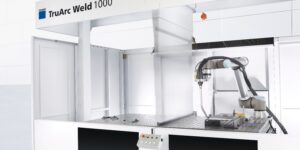

Moving beyond high-mix, low-volume welding work, cobots are more and more suitable for laser welding, becoming increasingly more portable, and are incorporating coordinated motion to optimize cycle times.

How pre-engineered weld cells can benefit business of all sizes.

With the addition of intelligent functionality, cobotic arc-welding cells are only becoming more profitable for any shop to operate.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

Minimize tool replacement expenses, while maintaining consistent and quality output.

Machine tool accessories reduce downtime and speed up your machining operations.

The technology behind ceramic grains enhances their cutting efficiency and prolongs wheel life, ensuring superior results in even the most rigorous metalworking applications.

Modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Balancing tool assemblies set the stage for smooth machining that produces parts with consistent surface finish. Balancing also accelerates production because speeds and feeds can increase without compromising the part.

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.