May 2024

Digital Issue

Elevate Your Tooling & Workholding: Is your shop benefiting from the latest optimal tooling and workholding products? This issue's cover story provides an in-depth look at tooling and workholding solutions for metal cutting and machining that reduce inventories, change over times and downtime, while improving quality and precision. Advantages such as stronger multilayer coatings that handle diverse operations on a range of materials, and easy-to-use and easy-to-install devices for use on multiple complex parts increase productivity on the shop floor. Discover the innovations that are creating the shape of things to come in the metalworking industry.

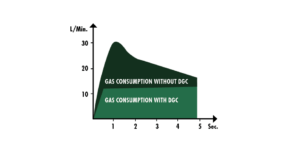

Subscribe View Digital IssueUnique, innovative, easy to use and flexible welders and welding components support a wide range of applications, providing consistent welding performance.

Ensuring consistency and saving money across a weld fleet has never been easier.

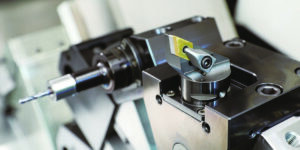

With EDMs your shop benefits from high precision cutting on components that can be difficult to manufacture.

Pre- and post-transaction planning is an essential part of the business succession process and should start months and sometimes years before the sale and often carry on months and sometimes a year or two after the sale.

With EDMs your shop benefits from high precision cutting on components that can be difficult to manufacture.

Even though laser-cutting systems have become more efficient with greater power levels, the industry faces some of the same problems.

Cincinnati partners with fabricators to examine where they are today and where they want to be in the future, building road maps and pathways to integrate technology and automation into their operations when it makes the most sense.

Improve the quality of your output, lower your costs, and maintain your competitive edge.

Utilizing the proper metalworking coolants and fluids not only extends the life of your machines but contributes to a safer shop environment.

When you put real thought into your selection of tool holders the job goes off without a hitch, even faster than anticipated.

Unique, innovative, easy to use and flexible welders and welding components support a wide range of applications, providing consistent welding performance.

Ensuring consistency and saving money across a weld fleet has never been easier.

Cincinnati partners with fabricators to examine where they are today and where they want to be in the future, building road maps and pathways to integrate technology and automation into their operations when it makes the most sense.

Choosing the right MIG gun directly affects efficiency, quality and safety — a trifecta every operator is trying to master to create a more comfortable and effective environment.

Shops benefit from the results of consistent deburring and finishing processes, batch after batch, to increasing their productivity and decreasing costs.

Is your shop benefiting from the latest optimal tooling and workholding products?

AI is increasingly being integrated into vision inspection systems to enhance their capabilities.