June/July 2024

Digital Issue

Smart Sustainability: We explore the products that are supporting metalworking's role in sustainability, addressing environmental-related concerns before they surface. Among other advantages, these initiatives improve quality, lower costs and drive overall equipment effectiveness. What's more, sustainable manufacturing sets you apart from the competition — and it is good for the bottom line.

Subscribe View Digital IssueThe synergy between robotics, automation, software, and machine controls is driving innovation throughout the metalworking industry.

Laser welding unlocks workforce capacity with easy-to-master techniques for new employees, leaving experienced welders time to focus.

The enhanced accuracy and rigidity of chucks and collets improves your shop’s overall machine performance.

The synergy between robotics, automation, software, and machine controls is driving innovation throughout the metalworking industry.

IMTS – The International Manufacturing Technology Show will be held at Chicago’s McCormick Place, September 9-14.

Innovations in machining technologies and processes optimize gear manufacturing.

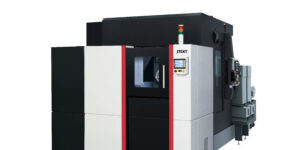

Multiple processes in one compact machine result in advantages without sacrificing precision and efficiency.

Laser welding unlocks workforce capacity with easy-to-master techniques for new employees, leaving experienced welders time to focus.

Minimize defects, and most importantly, keep your operators safe with the latest surface prep tools.

Top considerations shops should weigh when automating weld processing. When it comes to work cells, more players in the industry are offering mobile carts, AI path programming and more.

Precision sensors and controls keep pace with stringent quality standards to ensure your shop meets environmental compliance requirements.

The enhanced accuracy and rigidity of chucks and collets improves your shop’s overall machine performance.

CERATIZIT hosted Open Days 2024 in April where it showcased its sustainability initiatives and various new production facilities, sales and technical centers and much more.

Streamline the tool setup process and gain highly accurate measurements with minimal operator intervention.

Often a tool presetter is the first step on a shop’s journey to more efficient manufacturing.