January 2024

Digital Issue

State of the Industry: Digital Transformation, AI & Cybersecurity. Welcome to 2024... where the road to digital manufacturing, cybersecurity and AI is paved with endless possibilities. There is a great deal of buzz about these issues, and the opportunities and available solutions to achieve success. How best can the metalworking industry cut through the noise and realize the advantages and benefits? We spoke with manufacturing experts from the metalworking sector who provided tips as to strong starting points when implementing these solutions. They discussed the safety of the cloud, and ways to manage the copious amounts of data that are generated about your manufacturing processes and machine health. Uncover the leading ways you can benefit from a smart(er) shop in this month's cover story.

Subscribe View Digital IssueManufacturers implement Infor’s AI- and ML-enabled cloud software suites to stay on top of customers’ shifting demand patterns, create supply chain resiliency, and improve both client and employee experiences.

Higher quality filler metals may be more expensive up front, but what they save in weld prep, rework and weld quality can have positive financial impacts across the entire production cycle.

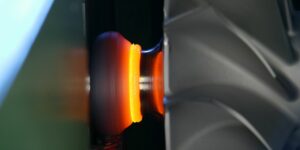

Friction welding processes — both FSW and RFW — offer a unique blend of efficiency and productivity in a growing range of contemporary applications.

Manufacturers implement Infor’s AI- and ML-enabled cloud software suites to stay on top of customers’ shifting demand patterns, create supply chain resiliency, and improve both client and employee experiences.

Safe and secure power tools and magnetic drills create environments that not only protect employees but also increase productivity.

Manufacturers implement Infor’s AI- and ML-enabled cloud software suites to stay on top of customers’ shifting demand patterns, create supply chain resiliency, and improve both client and employee experiences.

When it comes to automation, the best place to start is with a comprehensive, central automation software system that will link your machines.

The emergence of new advanced remote robot monitoring and control capabilities in the fabrication and metalworking sectors marks a new era in combatting downtime, while protecting companies from cybersecurity risks.

Higher quality filler metals may be more expensive up front, but what they save in weld prep, rework and weld quality can have positive financial impacts across the entire production cycle.

Friction welding processes — both FSW and RFW — offer a unique blend of efficiency and productivity in a growing range of contemporary applications.

Innovative, durable and versatile weld fume control products can easily be integrated into existing systems to create a more efficient use of your shop’s workspace.

Leading-edge sensors and automated systems establish shop floor environments where humans and robots can interact safely.

Improvements in personal protective equipment result in dependable, rugged and reliable protection for metalworkers.

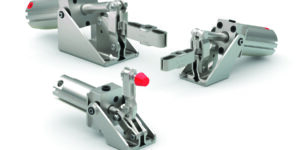

Efficient and adaptable workholding tools create significant improvements in metalworking applications.

Next generation shrink-fit tooling technologies get the work done in record time and keep your operators safe.

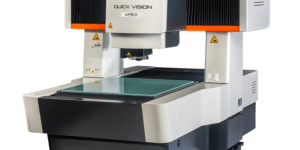

3D metrology, lasers and scanners have adapted to meet the specific challenges posed by new product developments.