February 2014

For those shops that are just getting started with live tools, guest columnist Preben Hansen of Heimatec shares this short primer on tooling that will assist you in equipping your next machines.

In an age of compromised files and records, your CNC can be one safe place. There’s more than a password involved: soft keys, key switches and conventional keyboards alike can be used to structure CNC security levels, enabling machine operators, setup personnel, maintenance technicians, programmers and master control personnel varying degrees of access to programs, tool settings and more.

Which welding variables affect weld penetration? How can you get more or less penetration in a weld?

The improved affordability of automation and its impressive returns on investment are sweeping through the shop floors of metal fabrication as robots and advanced motion control systems replace the human hands once needed to handle and process material.

The Dyna-Press from LVD Strippit delivers bending speeds up to 59 ipm to handle maximum bend lengths up to 33 deg and 12 ton bending force.

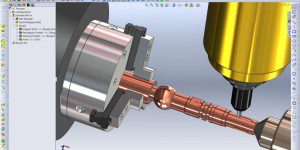

In today’s manufacturing environment, software has evolved. No longer designed for simple NC code and nesting parts for the best material utilization, it has become an increasingly useful and necessary tool for any production facility. Look for software modules which can be tailored to your needs and can create an ideal interaction between machine, control system, and production software.

Nothing is changing faster or more profoundly than the software used to design and machine parts. To help shops keep up with the latest competitive advances being introduced on the shop floor, here is a report on some of the newest CAD/CAM software.

The DMG Mori machine tools used by Hunting Energy Services play a crucial role in manufacturing well intervention equipment and threaded tubulars for the oil and gas industry.

Alstom Brazil Goes into Production using a massive XXL-sized vertical turret lathe from Schiess that has been brought into operation near Sao Paulo.

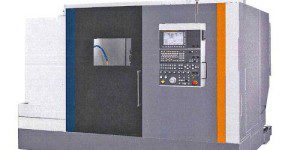

The Takisawa TS-4000YS horizontal turning center features a heavy-duty twin spindle, 12 station power turret with Y-axis, 30 hp main spindle motor and a 10 hp milling motor.

The T1 from Makino is ideal for large parts commonly machined in the energy and aerospace industries. The torque and power of the 12,000 rpm spindle make it highly productive in the machining of non-ferrous, ferrous and hard-metal materials, putting shop owners in a unique position to deliver highly competitive machining solutions for workpieces of any shape and any material.

In an age of compromised files and records, your CNC can be one safe place. There’s more than a password involved: soft keys, key switches and conventional keyboards alike can be used to structure CNC security levels, enabling machine operators, setup personnel, maintenance technicians, programmers and master control personnel varying degrees of access to programs, tool settings and more.

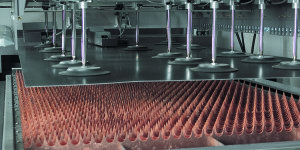

Automated threaded wheel grinding on gear production machines has now been boosted by an order of magnitude with increased machining accuracy to DIN class 3.

As automation sweeps through the welding industry, the need for weld data beyond just productivity and quality metrics increases. Basic welding information systems provide the operator with real-time information to drive continuous improvement during the actual fabrication of a component. As with any investment in the welding operation, consulting a trusted power source manufacturer or welding distributor is a good first step in determining the most appropriate technology to meet a company’s needs.

Which welding variables affect weld penetration? How can you get more or less penetration in a weld?

The latest machine condition monitoring technologies for steel mill suppliers of flat sheet, coil and structural metals can be tailored to monitor critical equipment assets operating in a wide range of harsh functional environments, process parameter changes, variable and low-speed equipment, shock loads and frequent setups. For shops, there is also virus protection for machine tools.

The flush mounting compact BMF 243 drop-in C-slot sensor for position detection from Balluff offers high performance reserves for cylinders with both weak as well as with strong magnets and offers high repeat accuracy and small hysteresis.

In the midst of a U.S. manufacturing renaissance, the disastrous rollout of Obamacare could put a crimp on manufacturers – particularly small shops. Of the nearly 11,000 pages (and counting) of new regulations imposed by this new law, no one really understands the full impact that lies ahead, what new regulations will be added, or how other arcane portions of the law will be changed in the future. Here is a general review of what we do know so far.

The dangers of distraction while working have garnered a great deal of attention. Distraction increases the risk of injury, but taking the appropriate steps to reduce distraction are neither easy nor simple. Much thought must be given to the consequences, fairness, and practicality of any regulations aimed at reducing the risks associated with worker distraction.

To improve the machining of one of their key products, this leading German metalworking firm turned to a solid carbide modular milling system that yielded big gains in accuracy and productivity.

In their search to reduce production cycle times, lower tooling costs and achieve higher precision machining of new materials, shops are demanding new cutting tool solutions that meet higher machining parameters, more process complexity, exotic alloys and a variety of other challenges. Here are some of the newest cutting tools that meet these needs.

For those shops that are just getting started with live tools, guest columnist Preben Hansen of Heimatec shares this short primer on tooling that will assist you in equipping your next machines.

Many sensors are often needed to measure certain dimensions, such as the flatness of a large surface, the taper of a long part, or large complex parts found in automobile and aerospace manufacturing. Here are two new systems to help shops expand their capabilities in multipoint inspection.